Acciaio Fe 360 e simili

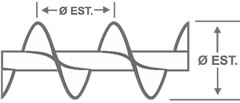

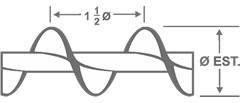

• OUTER DIAMETER: according to the strip width and inner diameter.

• INNER DIAMETER: in view of the shaft, even less than 1/5 of the outer diameter.

• PITCH: same as the outer diameter. For special conveyors, a different pitch, even less than 2/3 of the outer diameter or more than 1.5 times the diameter can be provided.

• GAUGE: approx. twice as the outer gauge on the inner diameter.

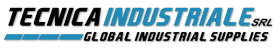

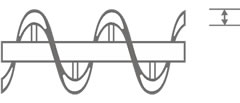

• COILING DIRECTION: to the right and to the left to be specified upon order.

Rotazione in senso orario

Attenzione: capovolgendo la spirale non cambia il senso di rotazione

| TOLERANCE | |||

| RATED OUTER DIAMETER |

INNER DIAMETER | PITCH | OUTER DIAMETER |

| fino a 150 mm. | -0 + 20/10 | ± 5 % | – 8/10 + 20/10 |

| 150 – 250 mm. | -0 + 25/10 | ± 5 % | – 8/10 + 25/10 |

| 250 – 500 mm. | -0 + 32/10 | ± 5 % | – 20/10 + 42/10 |

STANDARD PITCH (SQUARE):

pitch equal to the outer diameter for almost all types of conveyors.

REDUCED PITCH:

used for mixers and conveyors with a slant of more than 20° (usually a reduction down to 2/3 of the outer diameter, if the outer diameter exceeds 300 the reduction shall be higher).

EXTENDED PITCH:

for fast conveyors of running materials or for liquid mixers. (even more than 1.5 times the outer diameter

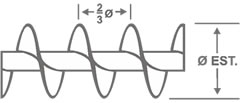

SPIRAL STRIP:

for viscous or damp material transportation for snowplow. etc. (sticking between coil and shaft is avoided)

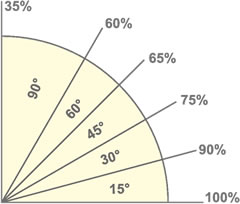

Influence of the slant on conveyor rate

The hourly conveyor RATE varies considerably depending on the product to be conveyed: size, humidity, auger diameter, slant, speed of rotation, filling degree, etc.

Please see the table below for the indicative values for grain conveyors with an 80 diameter spiral (100 diameter tube)

650/700 rpm see table below.

| Slant | 0° | 15° | 30° | 45° | 60° | 90° |

| Conveyor rate t/h | 10 | 9 | 7,5 | 6,5 | 6 | 3,5 |

INOX AISI 304 Spirals - 3 mt. bars

|

CODE |

EXT. |

PASSO |

PITCH mm. |

PER SHAFT of mm. |

Kg/mt. |

|

|

Sx |

Dx |

|||||

| 0229 | 01 | 50 | 50 | 13.5 | 2.2 | 0.98 |

| 0308 | 60 | 60 | 21.3 | 1.8 | 0.90 | |

| 0163 | 60 | 60 | 26.9 | 2.0 | 0.85 | |

| 076 | 65 | 65 | 30.3 | 2.0 | 0.85 | |

| 0173 | 04 | 80 | 80 | 21.3 | 2.5 | 1.70 |

| 0285 | 05 | 80 | 80 | 26.9 | 2.4 | 1.58 |

| 06 | 031 | 80 | 80 | 33.7 | 2.7 | 1.40 |

| 061 | 0127 | 90 | 90 | 26.9 | 2.4 | 1.90 |

| 041 | 040 | 100 | 100 | 21.3 | 2.0 | 1.87 |

| 08 | 07 | 100 | 100 | 26.9 | 2.5 | 1.99 |

| 085 | 100 | 70 | 33.7 | 2.5 | 2.50 | |

| 037 | 035 | 100 | 100 | 33.7 | 2.5 | 2.00 |

| 0251 | 110 | 110 | 42.4 | 2.5 | 1.95 | |

| 0283 | 120 | 80 | 33.7 | 2.0 | 3.13 | |

| 0178 | 120 | 120 | 26.9 | 2.0 | 2.46 | |

| 010 | 09 | 120 | 120 | 33.7 | 2.2 | 2.47 |

| 011 | 130 | 130 | 33.7 | 2.4 | 2.63 | |

| 090 | 082 | 130 | 130 | 42.4 | 2.2 | 2.51 |

| 0213 | 091 | 150 | 150 | 33.7 | 2.0 | 3.00 |

| 0123 | 012 | 150 | 100 | 48.3 | 2.4 | 3.93 |

| 014 | 013 | 150 | 150 | 48.3 | 2.4 | 2.94 |

| 0121 | 0120 | 150 | 150 | 60.3 | 2.5 | 2.76 |

| 028 | 015 | 160 | 160 | 48.3 | 2.4 | 3.01 |

| 019 | 180 | 100 | 60.3 | 2.2 | 5.02 | |

| 0114 | 180 | 120 | 60.3 | 2.3 | 4.65 | |

| 0128 | 180 | 120 | 70.0 | 2.6 | 5.08 | |

| 018 | 017 | 180 | 180 | 48.3 | 2.4 | 3.56 |

| 093 | 092 | 180 | 180 | 60.3 | 2.4 | 3.42 |

| 0135 | 190 | 190 | 42.4 | 2.0 | 3.35 | |

| 021 | 020 | 200 | 200 | 48.3 | 2.0 | 3.45 |

| 0214 | 0199 | 200 | 150 | 60.3 | 2.3 | 4.00 |

| 023 | 022 | 200 | 200 | 60.3 | 2.3 | 4.00 |

| 026 | 024 | 220 | 220 | 60.3 | 2.3 | 4.30 |

| 095 | 230 | 230 | 48.3 | 2.0 | 4.50 | |

| 0150 | 0208 | 230 | 230 | 60.3 | 2.0 | 4.23 |

| 026 | 025 | 250 | 250 | 60.3 | 2.0 | 4.35 |

| 049 | 048 | 250 | 250 | 70.0 | 2.0 | 4.34 |

| 0333 | 0332 | 250 | 200 | 76.1 | 2.0 | 5.34 |

| 0327 | 300 | 250 | 76.1 | 2.0 | 5.34 | |

| 0357 | 097 | 300 | 300 | 76.1 | 2.0 | 4.88 |

| 069 | 068 | 300 | 300 | 88.9 | 2.0 | 5.00 |

| 0175 | 300 | 300 | 88.9 | 3.0 | 7.52 | |

| 038 | 350 | 300 | 88.9 | 3.0 | 10.56 | |

| 0273 | 350 | 350 | 88.9 | 3.0 | 9.00 | |

| 079 | 0995 | 400 | 400 | 101.6 | 4-3.3 | 10/11 |

| 0330 | 400 | 400 | 114.3 | 4-3.3 | 10.51 | |

Continous iron spirals - 3 mt. bars

|

CODE |

EXT. DIAMETER |

PASSO |

PITCH mm. |

PER SHAFT of mm. |

Kg/mt. |

|

|

Sx |

Dx |

|||||

| 474 | 809 | 50 | 47 | 13.5 | 1.7 | 0.70 |

| 2 | 1 | 50 | 50 | 13.5 | 1.7 | 0.70 |

| 188 | 187 | 60 | 60 | 21.3 | 1.7 | 0.90 |

| 9 | 8 | 70 | 70 | 17.2 | 1.5 | 1.10 |

| 11 | 10 | 80 | 80 | 17.2 | 1.7 | 1.30 |

| 13 | 12 | 80 | 80 | 21.3 | 1.7 | 1.30 |

| 15 | 14 | 80 | 80 | 26.9 | 1.7 | 1.15 |

| 631 | 17 | 85 | 85 | 21.3 | 1.8 | 1.55 |

| 20 | 19 | 90 | 90 | 26.9 | 1.7 | 1.40 |

| 22 | 21 | 100 | 100 | 21.3 | 1.6 | 1.55 |

| 24 | 23 | 100 | 100 | 26.9 | 1.7 | 1.60 |

| 27 | 26 | 100 | 100 | 33.7 | 1.8 | 1.50 |

| 31 | 30 | 120 | 120 | 26.9 | 1.6 | 1.90 |

| 37 | 36 | 120 | 120 | 33.7 | 1.8 | 1.90 |

| 39 | 38 | 130 | 130 | 26.9 | 1.6 | 2.00 |

| 41 | 40 | 130 | 130 | 33.7 | 1.7 | 2.00 |

| 43 | 42 | 130 | 130 | 42.4 | 1.7 | 1.90 |

| 47 | 46 | 135 | 135 | 26.9 | 1.5 | 2.00 |

| 50 | 49 | 135 | 135 | 33.7 | 1.7 | 2.10 |

| 52 | 51 | 135 | 135 | 42.4 | 1.7 | 1.90 |

| 54 | 53 | 140 | 140 | 33.7 | 1.6 | 2.10 |

| 56 | 55 | 140 | 140 | 42.4 | 1.8 | 2.15 |

| 446 | 140 | 140 | 48.3 | 1.8 | 2.10 | |

| 62 | 61 | 150 | 150 | 33.7 | 1.6 | 2.50 |

| 64 | 63 | 150 | 150 | 42.4 | 1.7 | 2.10 |

| 65 | 150 | 100 | 48.3 | 1.7 | 3.45 | |

| 67 | 66 | 150 | 150 | 48.3 | 1.8 | 2.30 |

| 1059 | 68 | 150 | 150 | 48.3 | 4.0 | 4.70 |

| 1587 | 150 | 150 | 48.3 | 5.0 | 6.10 | |

| 481 | 150 | 150 | 60.3 | 2.0 | 2.20 | |

| 150 | 454 | 150 | 150 | 60.3 | 4.5 | 4.90 |

| 73 | 72 | 160 | 160 | 42.4 | 1.6 | 2.40 |

| 75 | 74 | 160 | 160 | 48.3 | 1.6 | 2.30 |

| 561 | 560 | 160 | 160 | 48.3 | 4.0 | 5.30 |

| 465 | 280 | 170 | 170 | 48.3 | 1.7 | 2.50 |

| 1376 | 409 | 180 | 180 | 28.0 | 1.7 | 2.90 |

| 267 | 1214 | 180 | 180 | 33.7 | 1.8 | 2.80 |

| 77 | 76 | 180 | 180 | 42.4 | 1.6 | 2.60 |

| 1362 | 180 | 180 | 42.4 | 4.0 | 6.30 | |

| 79 | 78 | 180 | 140 | 48.3 | 1.5 | 3.00 |

| 81 | 80 | 180 | 180 | 48.3 | 1.7 | 2.60 |

| 524 | 82 | 180 | 180 | 48.3 | 3.4 | 5.40 |

| 84 | 83 | 180 | 180 | 60.3 | 1.7 | 2.60 |

| 632 | 85 | 180 | 180 | 60.3 | 4.3 | 6.20 |

| 1588 | 180 | 180 | 60.3 | 6.0 | 8.60 | |

| 574 | 200 | 200 | 28.0 | 1.8 | 3.50 | |

| 674 | 200 | 200 | 28.0 | 3.0 | 5.80 | |

| 91 | 90 | 200 | 200 | 48.3 | 1.8 | 3.20 |

| 92 | 532 | 200 | 200 | 48.3 | 3.5 | 6.20 |

| 1610 | 200 | 200 | 48.3 | 5.3 | 10.10 | |

| 95 | 94 | 200 | 200 | 60.3 | 2.0 | 3.40 |

| 1213 | 255 | 200 | 200 | 60.3 | 3.7 | 6.00 |

| 1589 | 200 | 200 | 60.3 | 5.5 | 9.70 | |

| 97 | 96 | 210 | 210 | 48.3 | 1.8 | 3.40 |

| 98 | 1538 | 210 | 160 | 60.3 | 1.8 | 4.10 |

| 857 | 220 | 220 | 28.0 | 2.1 | 4.50 | |

| 858 | 220 | 220 | 28.0 | 2.8 | 6.40 | |

| 103 | 102 | 220 | 220 | 48.3 | 1.8 | 3.50 |

| 105 | 104 | 220 | 200 | 60.3 | 1.9 | 3.60 |

| 107 | 106 | 230 | 230 | 48.3 | 1.8 | 4.30 |

| 109 | 108 | 230 | 170 | 60.3 | 1.7 | 5.10 |

| 111 | 110 | 230 | 230 | 60.3 | 1.8 | 4.00 |

| 112 | 240 | 240 | 48.3 | 2.0 | 4.70 | |

| 113 | 240 | 240 | 60.3 | 2.0 | 4.50 | |

| 115 | 114 | 250 | 200 | 60.3 | 1.9 | 5.50 |

| 117 | 116 | 250 | 250 | 60.3 | 1.8 | 4.00 |

| 118 | 342 | 250 | 250 | 60.3 | 2.3 | 4.00 |

| 1590 | 250 | 250 | 60.3 | 5.5 | 12.00 | |

| 122 | 121 | 280 | 280 | 60.3 | 2.2 | 5.80 |

| 123 | 234 | 280 | 190 | 70.0 | 2.0 | 6.50 |

| 125 | 124 | 280 | 280 | 70.0 | 2.0 | 5.70 |

| 128 | 127 | 300 | 200 | 70.0 | 2.1 | 8.30 |

| 353 | 129 | 300 | 250 | 70.0 | 2.3 | 7.10 |

| 132 | 131 | 300 | 300 | 70.0 | 2.0 | 5.20 |

| 134 | 133 | 300 | 300 | 70.0 | 2.4 | 6.90 |

| 137 | 136 | 300 | 300 | 76.1 | 2.0 | 5.30 |

| 1591 | 300 | 300 | 76.1 | 5.6 | 14.15 | |

| 140 | 300 | 300 | 88.9 | 2.3 | 5.70 | |

| 143 | 142 | 350 | 250 | 88.9 | 2.3 | 9.20 |

| 146 | 144 | 350 | 300 | 88.9 | 2.4 | 8.40 |

| 480 | 479 | 350 | 300 | 88.9 | 3.5 | 11.50 |

| 148 | 147 | 350 | 350 | 88.9 | 2.3 | 8.40 |

| 150 | 149 | 350 | 350 | 88.9 | 3.1 | 10.50 |

| 152 | 151 | 350 | 350 | 114.3 | 2.5 | 7.00 |

| 1259 | 400 | 400 | 88.9 | 3.5 | 15.00 | |

| 158 | 157 | 400 | 350 | 101.6 | 3.6 | 14.50 |

| 160 | 159 | 400 | 400 | 101.6 | 2.0 | 7.20 |

| 162 | 161 | 400 | 400 | 101.6 | 4.0 | 14.00 |